4 TYPES OF MOULDED FIBRE

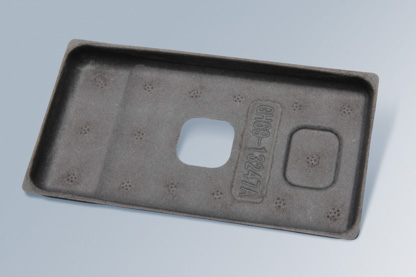

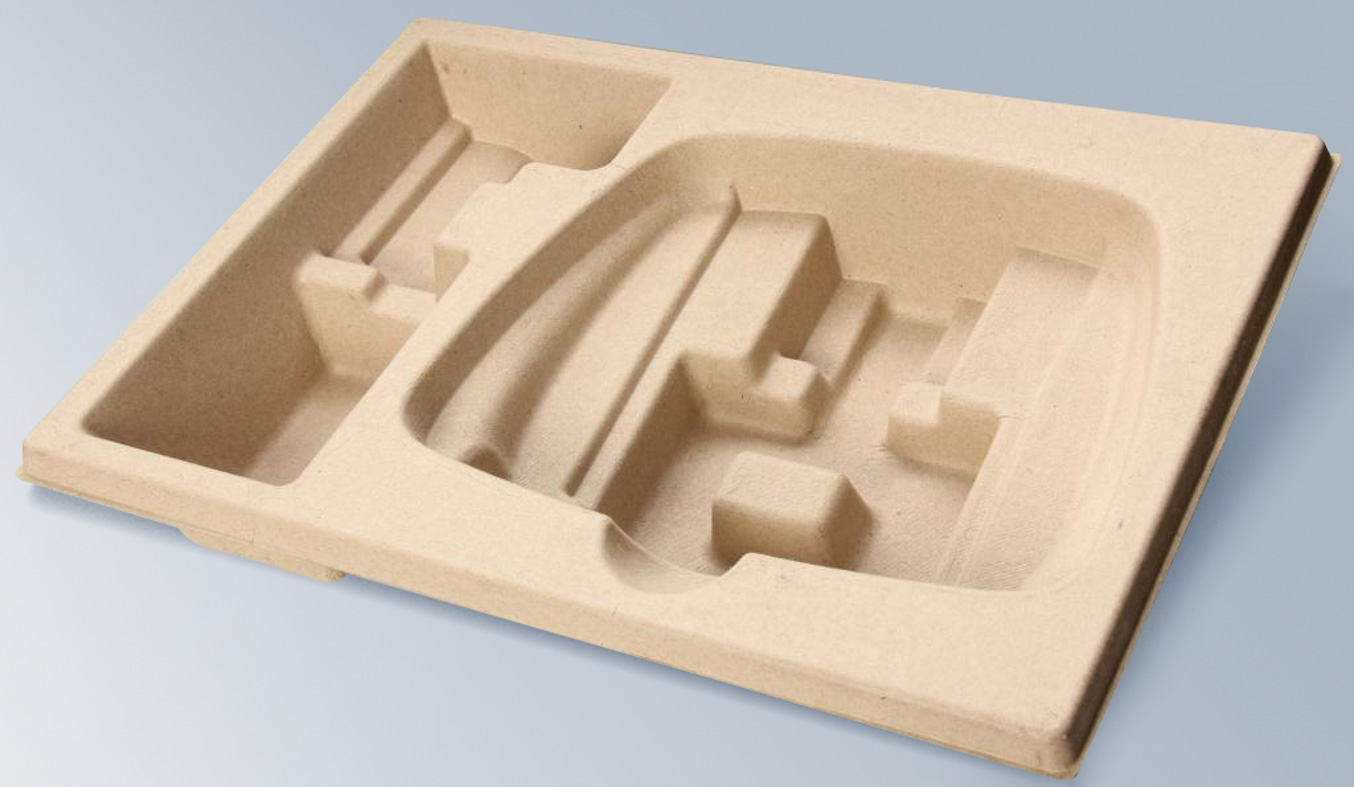

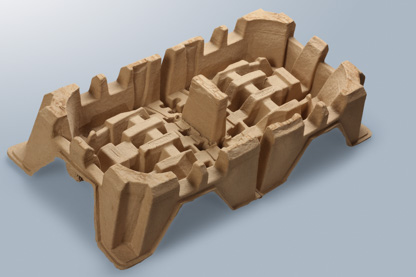

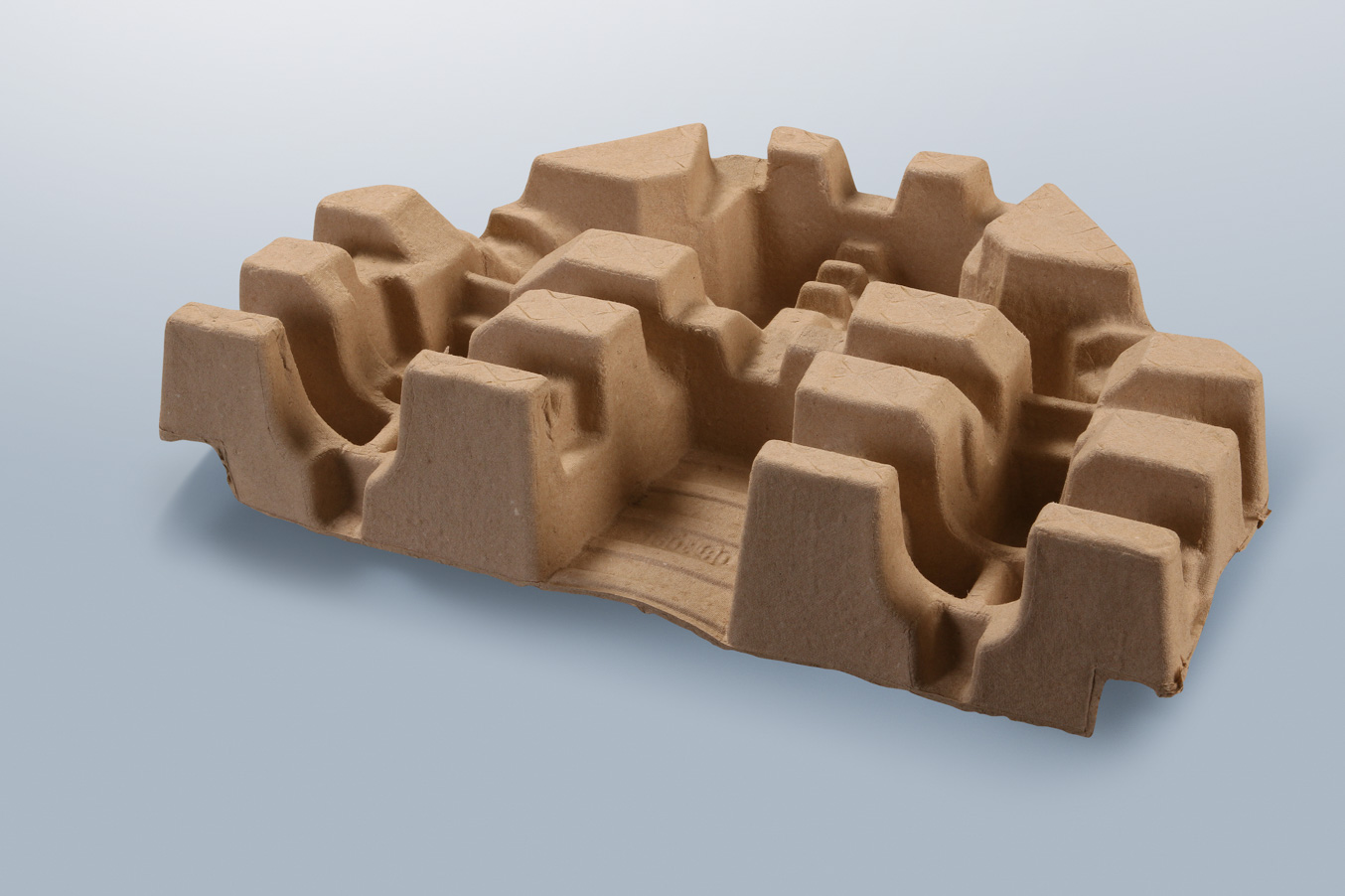

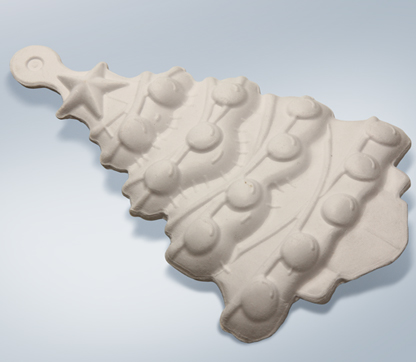

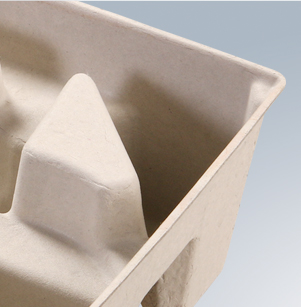

Formed

Basic type of moulded fibre product made on a conventional line. Finds use in many industrial and non-industrial sectors, such as B2B transport of automotive components etc. The rough surface of the product and its internal fibre structure give the tray high strength and rigidity. Thanks to its quick biodegradability, this type of moulded fibre is often used when planting decorative and agricultural crops.

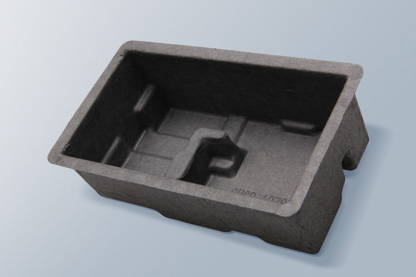

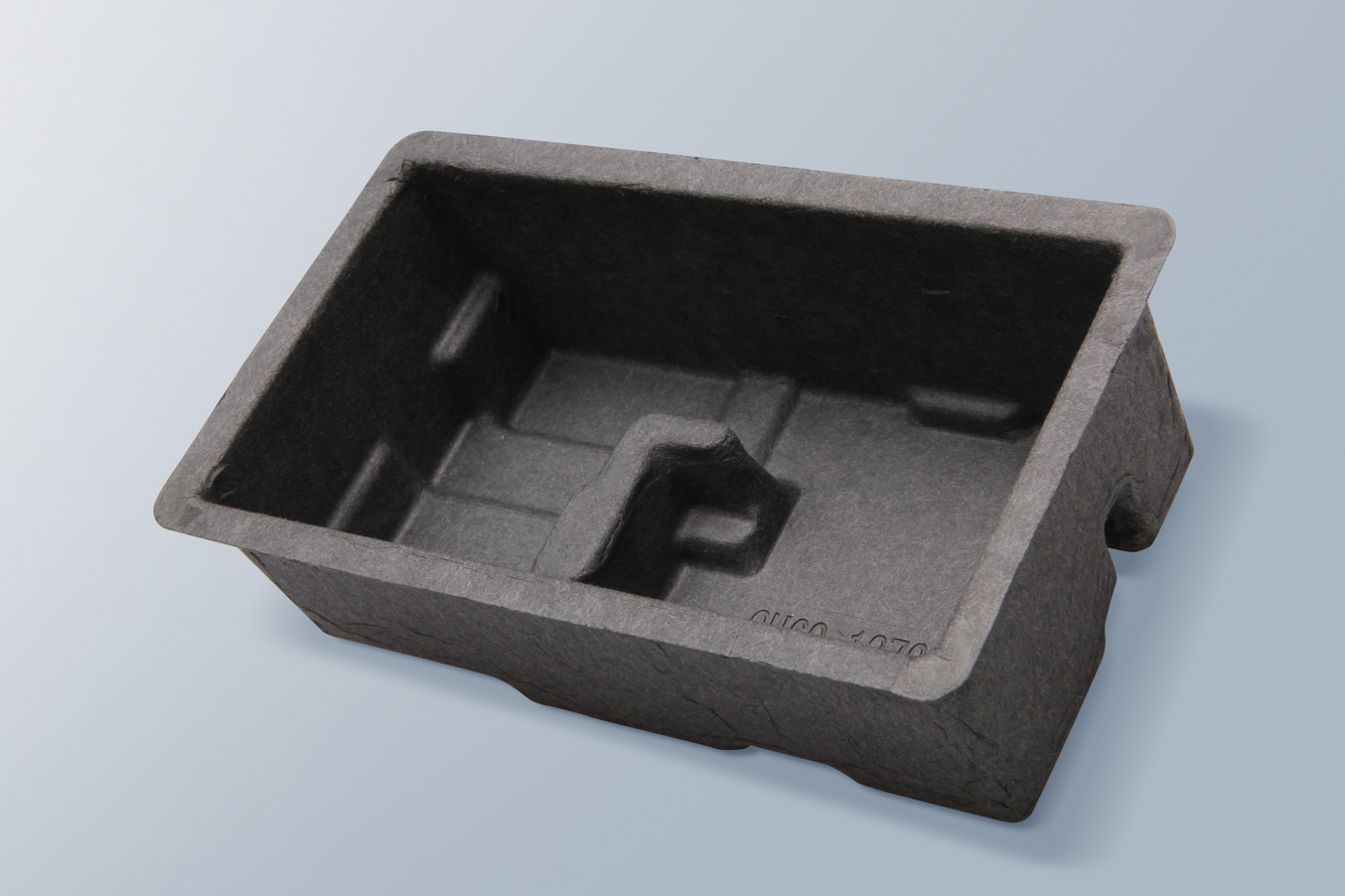

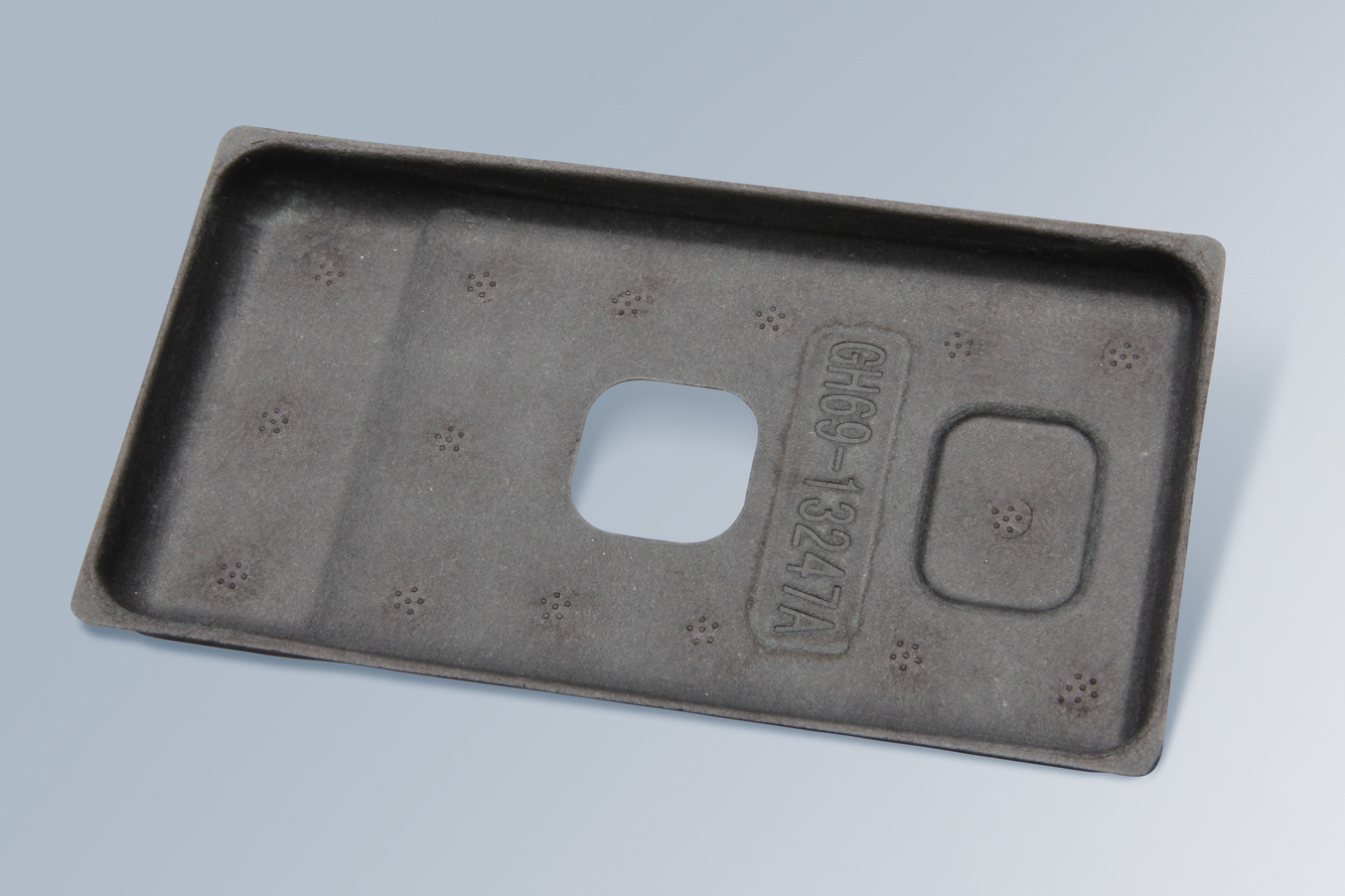

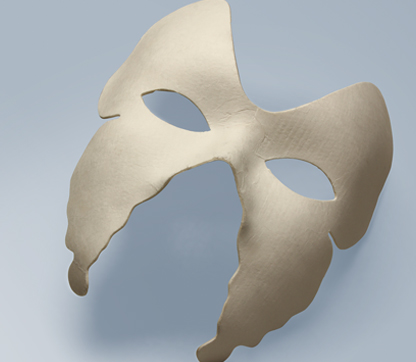

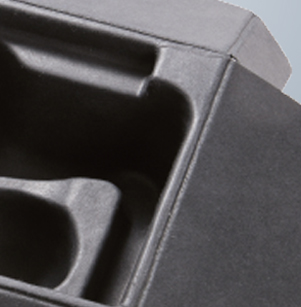

After-pressed

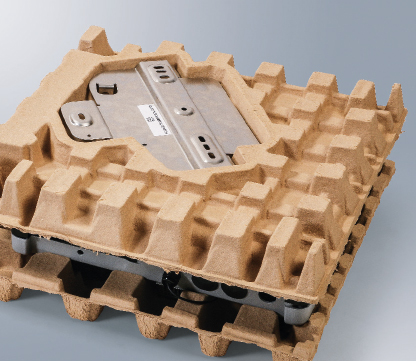

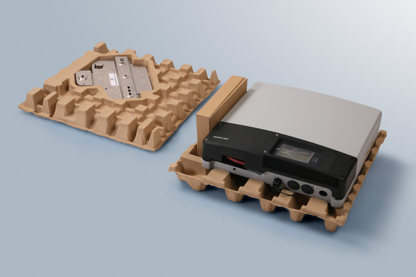

This more refined type of moulded fibre is produced on a conventional line like its formed counterpart, but is then after-pressed. After-pressing lends the material a smooth surface. Packaging made by this technique finds use particularly when packaging electronics, where it is increasingly replacing classic packaging materials made of plastic, polyester etc.

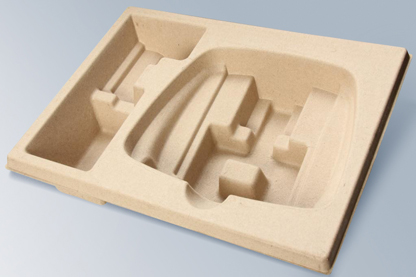

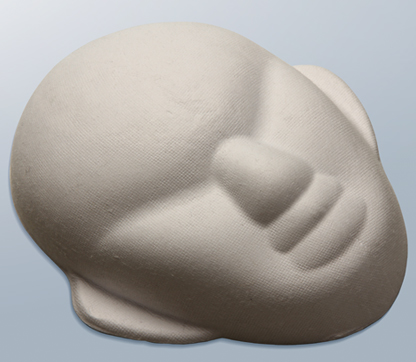

Thermoformed

This type of moulded fibre is produced on thermoforming lines. The product is dried in heated moulds and can therefore be produced in complex shapes, while maintaining a smooth surface. The technology allows for the creation of products such as recyclable and biodegradable paper tableware, paper cutlery or menu boxes, and thus offers a more sustainable substitute for plastic products.

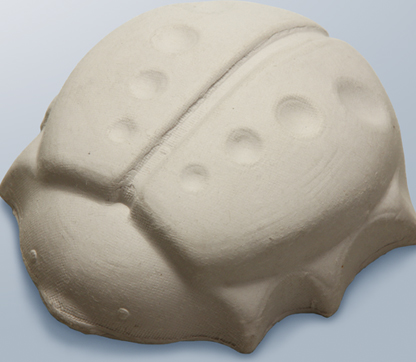

Processed

Processed moulded fibre products are most commonly produced via thermoforming. As opposed to classic paper thermoforming products, however, these products can feature a printed logo of your company and can come in various coloured designs. None of these modifications negatively affect recyclability and compostability.

The use Fields of application

of the moulded fibre

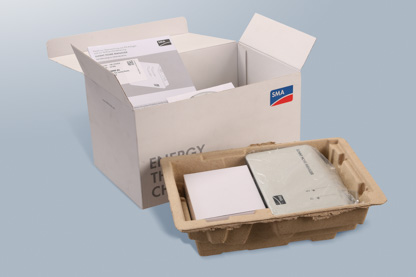

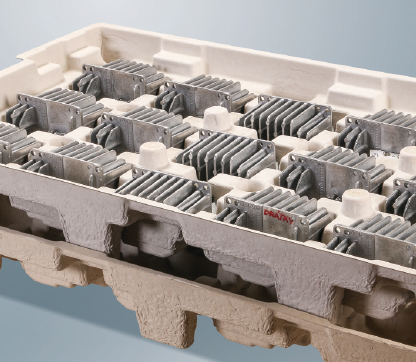

Electronics

Seen from many points of view, for electronics and for electronic appliances moulded fibre is an ideal choice due to its electrostatic neutrality. Moulded fibre enables to perfectly copy surface of a packaged product, of its primary package. Due to optimally designed deformation zones, minimized is a damage of a product, due to a drop test, which could be transferred to the packaged product.

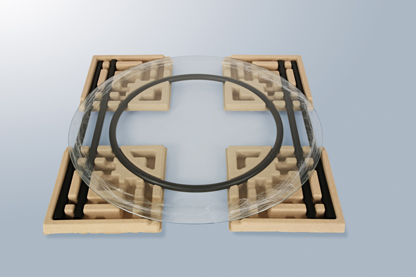

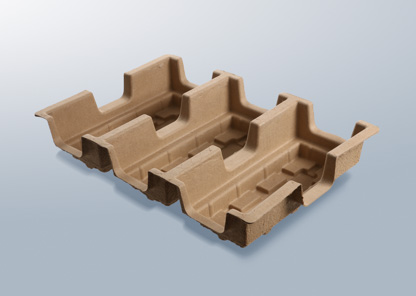

GalleryIndustry

Products of moulded fibre can be used for packaging within the whole light industry range, for example for fine glass products, furniture, cosmetics, and textiles, petty consumer goods, etc. Advantage is that moulded fibre may be formed to nearly any 3D shape, which enables individual packaging of any product or packaging of a complete product charge together.

GalleryAutomotive

Intelligent design enables to stack products without any contact between the goods. Precise shapes are also suitable for fully automatic processes. Tridas' products are frequently used in the production of LED light sources, LED lighting units, as well as for braking systems, touch display car radios, for packaging door locks, etc.

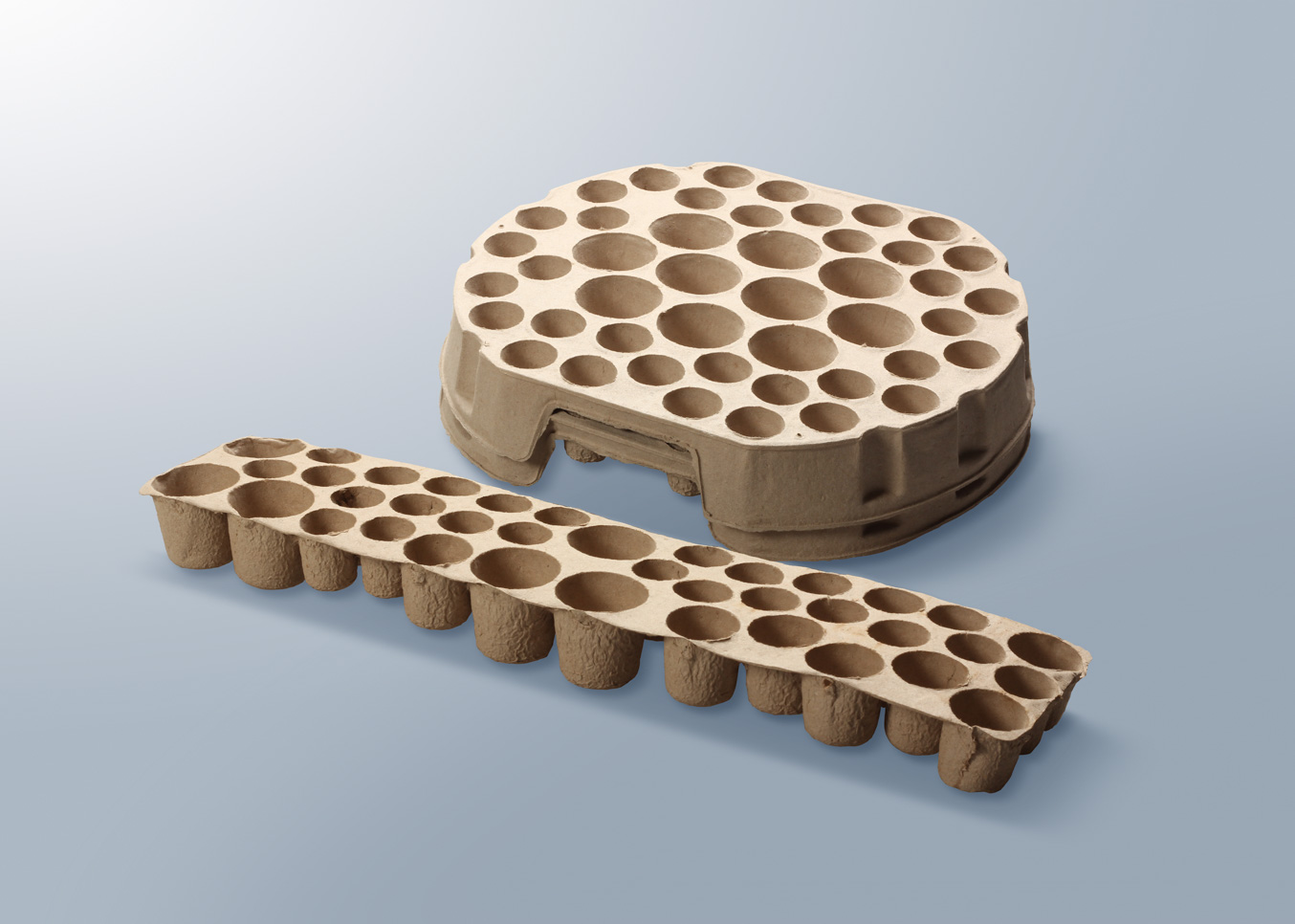

GalleryAgriculture

With respect to the zero content of dangerous substances and of heavy metals our products are used as disposable flowerpots that degrade, following after a flower has been planted, and they serve as fertilizer with a high carbon content. With a higher surface quality paper trays are used for packaging foodstuff for animals and as breeding stations for useful insects.

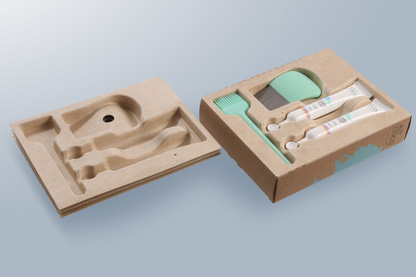

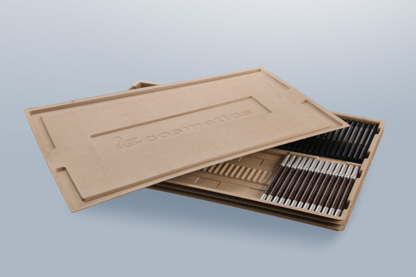

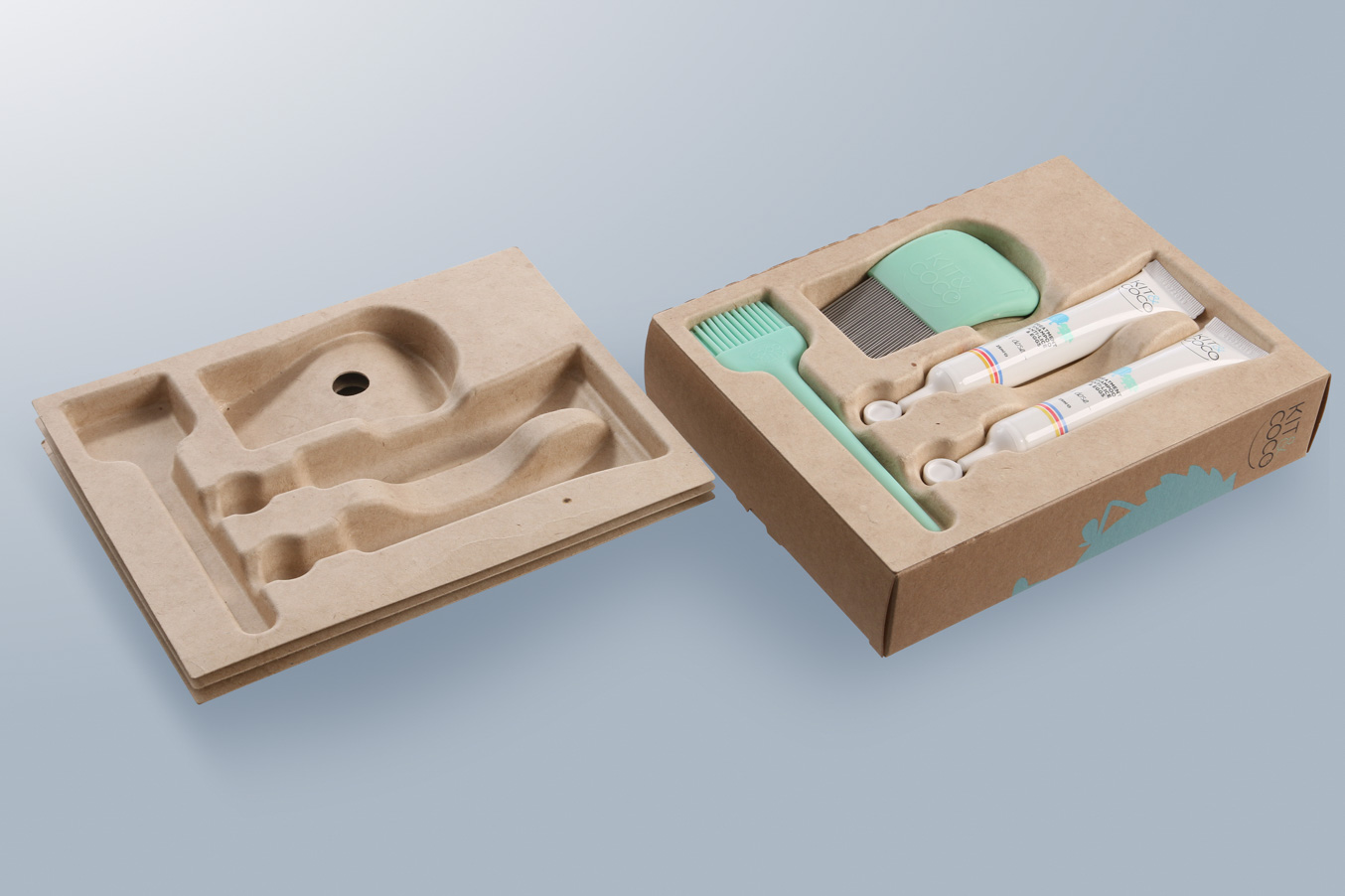

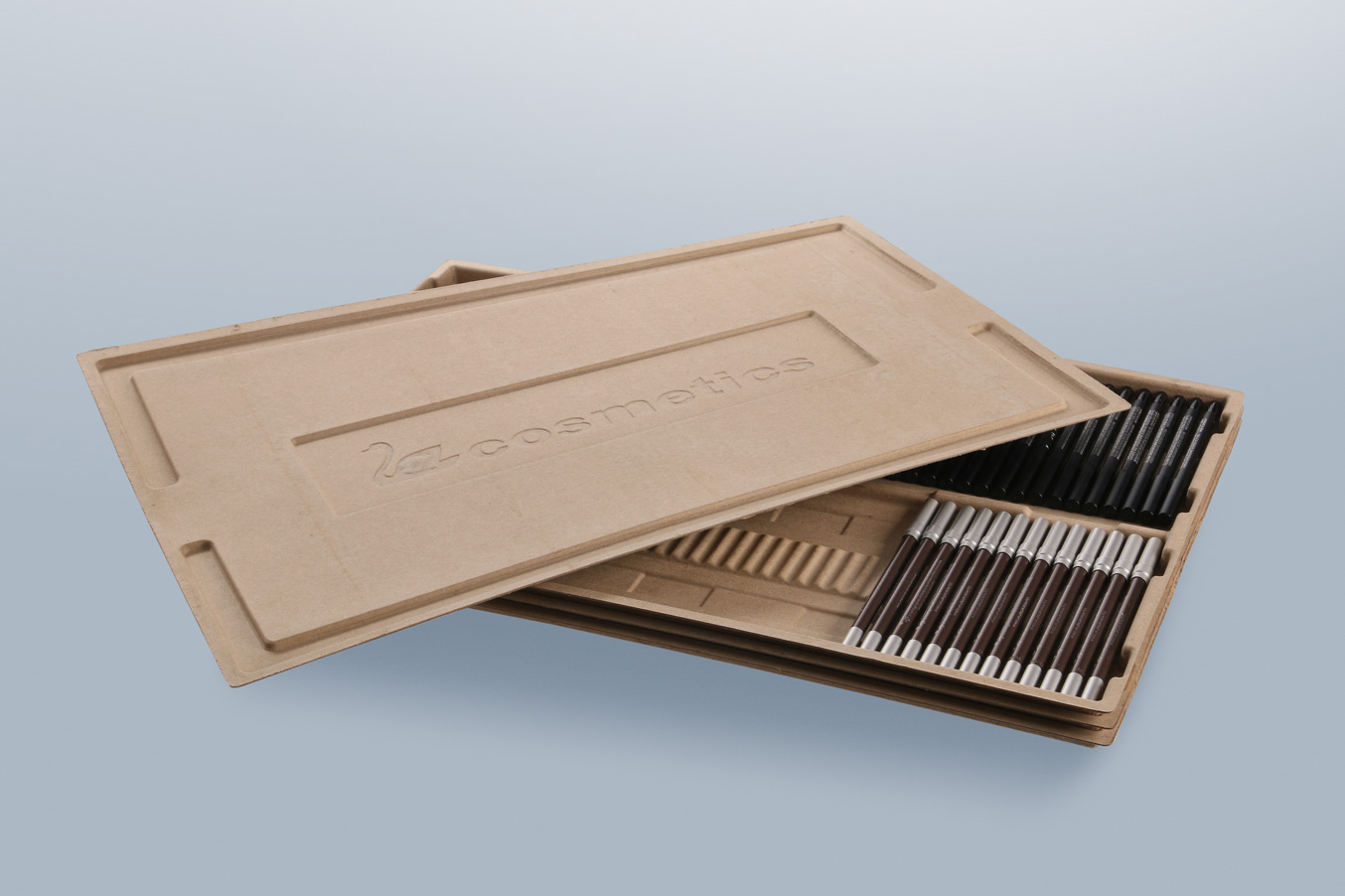

GalleryCosmetics

Clean and smooth surface enables packaging of fragile cosmetic preparations sensitive to dust. Such a package is suitable both for mass production and for a luxury final product. Full-colour print using 16 million hues and 600 dpi high resolution give a package highly exclusive nature; moreover, it may be personified both in small and large series.

Gallery